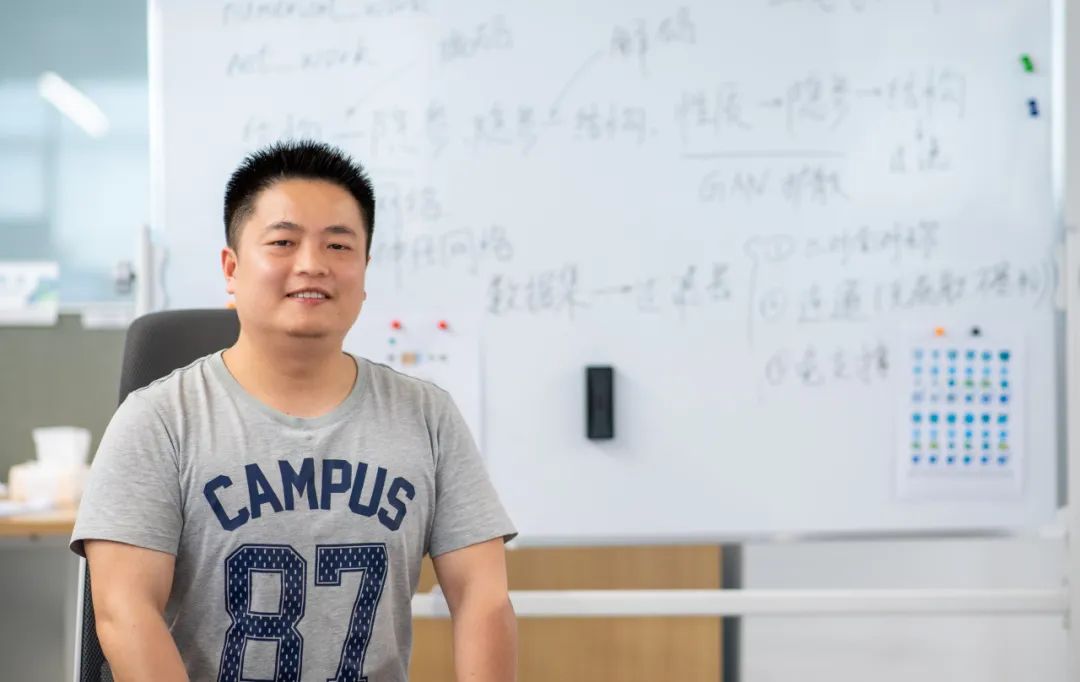

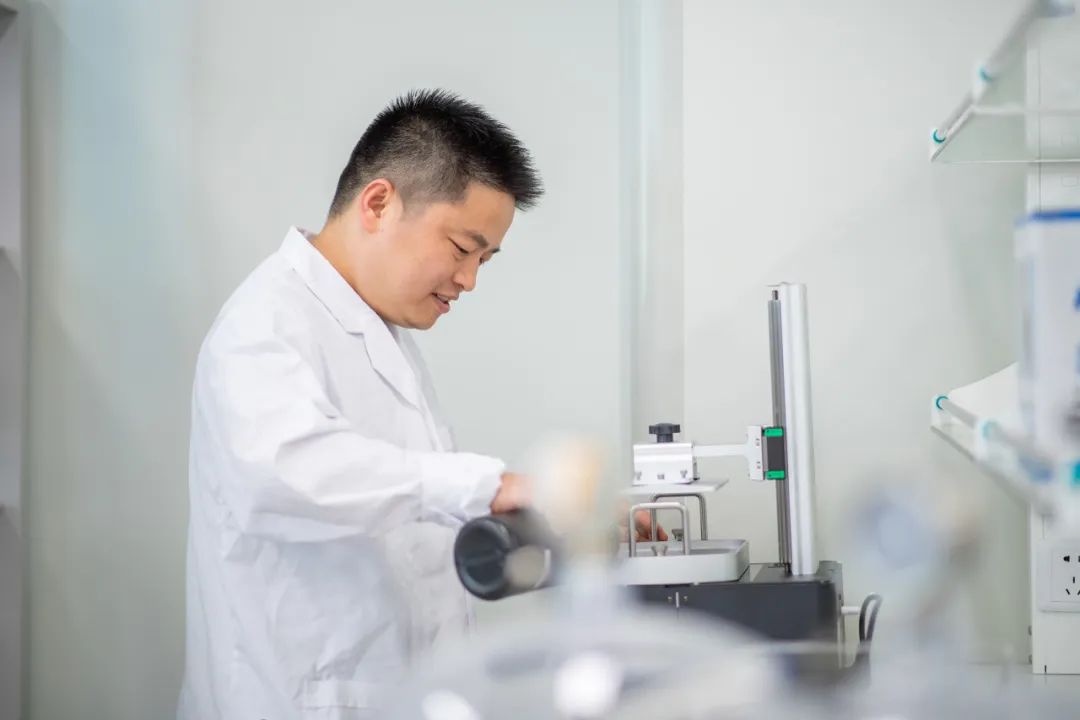

What is it like to do materials science research at a scientific research institution focusing on intelligent computing? NIE Daming, a senior research specialist at the Research Center for New Materials Computing of Zhejiang Lab (ZJ Lab), had his own insights.

NIE Daming is experienced in materials science research, who has studied and worked on materials science for more than ten years. During this period, he got deeply involved in the R&D and design of many projects such as high-performance electrical steels, large-size thin-walled structures with deformable cross sections, and lightweight designs for legs of humanoid robots, and also served as a university lecturer teaching major courses such as Fundamentals of Materials Science.

However, as NIE Daming delves deeper into the field of materials science, he increasingly perceives that as there are objective weaknesses in traditional materials science methodology, particularly in the research and development of new materials, the resulting problems have become more pronounced. "In the past, the research and development of new materials was based on massive experiments, where an individual experiment involved long-running and time-consuming processes and heavy workload, and it was highly dependent on large-scale expensive experimental facilities, leading to a long new product R&D lifecycle, high costs, and high manpower investment," said NIE Daming.

With the rise of "AI for Science" in recent years, intelligent computing has made many breakthroughs in promoting the development of fundamental subjects and accelerating scientific and technological innovations in key fields. Consequently, materials researchers have gotten involved more often than ever, including NIE Daming.

In 2023, ZJ Lab set up the Research Center for New Materials Computing based on its original research team, which is committed to creating a multi-scale materials intelligent computing platform, building an all-domain open materials computing ecosystem, and developing a "computing + data + model" driven new materials R&D paradigm. After joining the Research Center for New Materials Computing, NIE Daming quickly defined his research objectives and initiated preliminary research work. "I hope that metallic metamaterials suited for applications can be generated accurately through intelligent computing," said NIE Daming. "Now, we have initially built experimental data sets and are also debugging neural network models. The combination of "experiment + computing" enables us to establish a relationship between experimental parameters and results, and then accurately predict the material properties corresponding to a new round of experimental parameters, greatly reducing the time and costs of experimentation and speeding up the materials research and development."

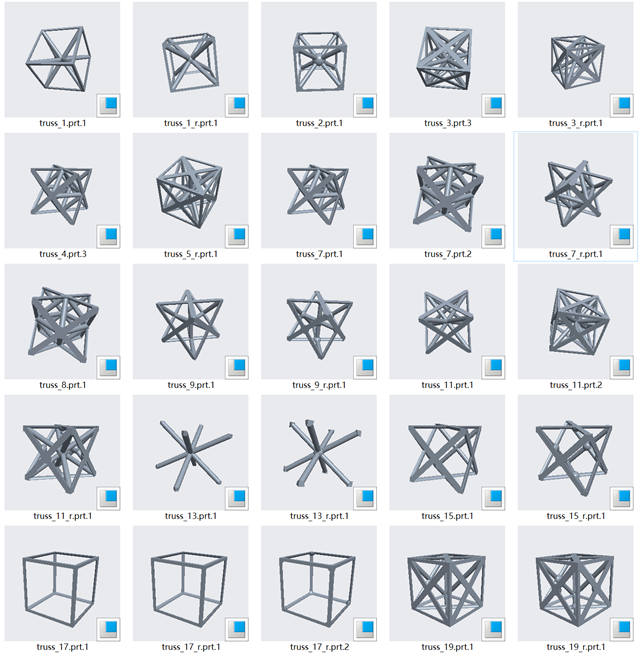

Batch-Generated Different Rod Cells

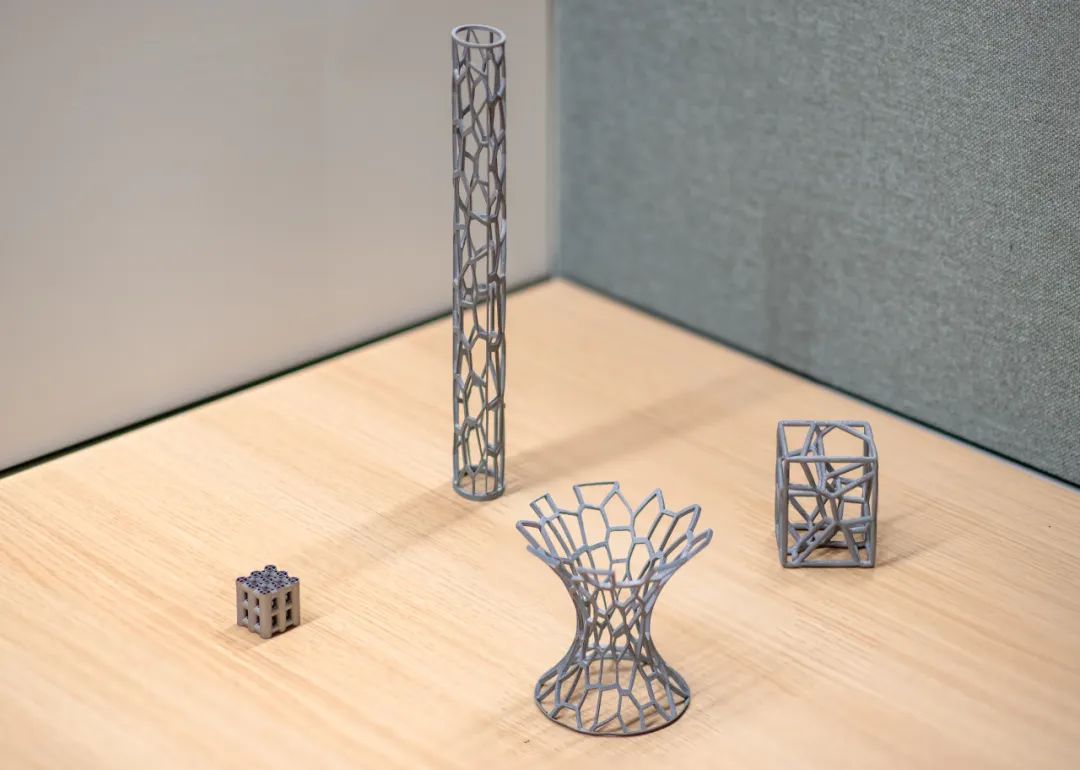

Sample 3D-Printed Metal Structural Component Filled with Metamaterials

The effective methodology has given NIE Daming enough confidence to promote the research and development of new materials. In ZJ Lab's "Lesson 1 of the New Year 2024", the Research Center for New Materials Computing signed the Research Task Responsibility Agreement with Academician WANG Jian, President of ZJ Lab, in which NIE Daming undertook one of the sub-tasks. "Our team is tasked with developing high-flux simulation computing capabilities supporting 3D printing of components of porous materials, processes and structures based on an open platform for intelligent computing of new materials, and opening our services up to the outside world. This requires us to make full use of industry data and AI agent models to realize the intelligent design of materials for metal 3D printing and reveal the correspondence between printing parameters and material properties, so as to automatically generate high-performance structural cells." NIE Daming said that this research will accelerate the research and development of better-performing new materials for 3D printing, and disclose the microstructure evolution of metals during 3D printing to the industry and academic circles, thus reducing spending on design, research and development of high-strength lightweight structures.

Everything is easier said than done, and the signing of the Responsibility Agreement is just the beginning. To improve research efficiency and tackle key problems, NIE Daming and his team members used an engineering approach to advance scientific research. "According to the Responsibility Agreement, we have defined clear node requirements for ourselves, and carried out job breakdown, time inversion, and division of labor. Once a node is found to fall behind schedule, my colleagues and I will work overtime to deal with the difficulties. In spite of high R&D intensity, we conduct research efficiently at a good pace."

NIE Daming's colleagues said that in the large office, the light hanging above his desk is often the last one to go out. "After all I am a researcher engaged in materials science, so I need to make up for my weaknesses by spending more time on self-learning and self-improvement in order to catch up with my colleagues' level of computing knowledge and accomplish the set goals with the team," said NIE Daming. Since self-learning alone isn't enough, NIE Daming often attends expert lectures and learning salons within the Research Center, and the researchers engaged in materials and computing take turns giving lectures to learn from each other and make progress together, from which NIE Daming benefits a lot. In addition to improving his research skills, NIE Daming also pays attention to the development status of the industry, understands the application needs, and then mobilizes his colleagues to tackle tough challenges from a global perspective. "A few days ago, I visited TCT Asia 2024, a metal 3D printing exhibition in Shanghai, and saw the new products and technologies from China's leading 3D printing enterprises and research institutions. Participating in such events can help us steer research in the right direction and make research plans."

Materials science is an ancient subject. For example, even during the Paleolithic era, cavemen recognized the importance of utilizing hard materials for crafting cutting tools., Several significant ages of civilization in human history were named after new materials widely used in those periods. "At ZJ Lab, I think we have found the right point from which new materials R&D is empowered with intelligent computing," said NIE Daming. "Hopefully, my colleagues and I can explore a new paradigm for research and development of new materials to provide generic technologies for the materials industry, thus speeding up new materials R&D, and scaling up applications of new materials. It would make me feel fulfilled, I think."